Imagine, you have seamless digital communication throughout your manufacturing floor. Possible? YES!

EQUIPMENT AUTOMATION

EAF Equipment Automation Framework

Connect equipment within your factory and provide seamless communication throughout your manufacturing floor

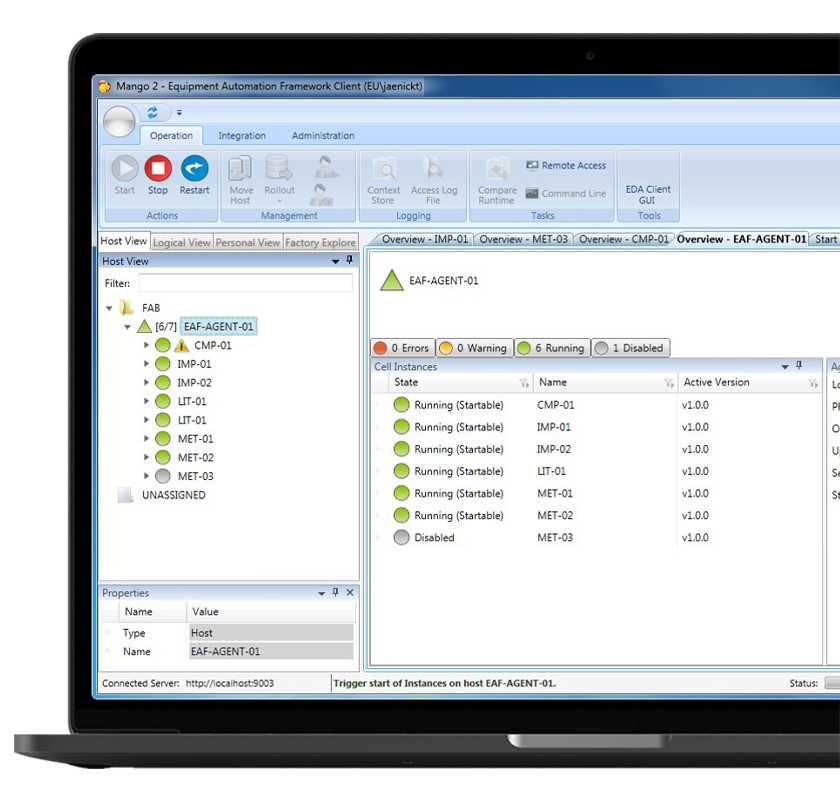

EAF is a flexible, customizable equipment automation framework that factories use to connect and integrate any type of industrial machinery. EAF also automates the flow of data throughout your factory.

Built on decades of experience gained from integrating equipment in highly-automated manufacturing environments like leading semiconductor fabrication facilities, EAF supports not only the latest factory automation and communications standards such as SEMI SECS/GEM or OPC-UA but also traditional connectivity methods like native PLC communication, custom protocols, file and/or database access.

Support smart production in your factory

Connect any type of equipment in any industry

EAF Datasheet Download

If you need more in-depth technical details, please download our EAF data sheet.

OUR SOLUTION

EAF Product Benefits

Intuitive

Configurable

Customizable

Cost-efficient

Inexpensive operation

High quality

High-availability

EAF Installation Base

USA

1 of 10Mexico

2 of 10Hungaria

3 of 10Austria

4 of 10Germany

5 of 10Singapore

6 of 10Malaysia

7 of 10China

8 of 10Indonesia

9 of 10South Korea

10 of 10Example customer

EAF deployment options

Factories use EAF to connect new or existing equipment.

Connect new equipment

EAF’s sophisticated modular architecture, high-availability features and centralized, intuitive configuration and management make equipment integrations easy in new-build manufacturing facilities. The same is true when existing production plants need capacity extensions or shall be modernized.

Connect existing equipment

Equipment connectivity helps modernizing your plant’s operations. EAF offers out-of-the-box adapters to provide a cost-efficient way to connect older equipment with limited or non-standardized interfaces.

Reconnect and replace outdated legacy systems

Its unique features and flexibility makes the Equipment Automation Framework the perfect choice as a replacement for your outdated legacy systems. If you’re in the process of migrating your existing equipment integration solution on a machine-by-machine basis, consider EAF. By utilizing our Automation Capability Management (ACM) Services and automation interface testing product, DiDaCT, we ensure a smooth transition without impacting production.

Connect equipment with an EAF layer when deploying MES

PEER Group GmbH collaborates with several MES providers to complement their ANSI ISA95 Level 3 functions with our expertise in the Automation Network domain (Level 2 and below). Our engineering experts play an active part in the development and enhancement of the automation and communication standards such as SEMI SECS and OPC UA, making our EAF-based integration services ideally suited for taking care of equipment connectivity challenges in MES partnerships.

Courtesy of Fraunhofer IPMS-CNT